Complete reliability, to provide confident care.

Signal accuracy, to ensure precision read-outs.

Size & weight savings, to enable device mobility.

Power savings, to lower total cost of ownership.

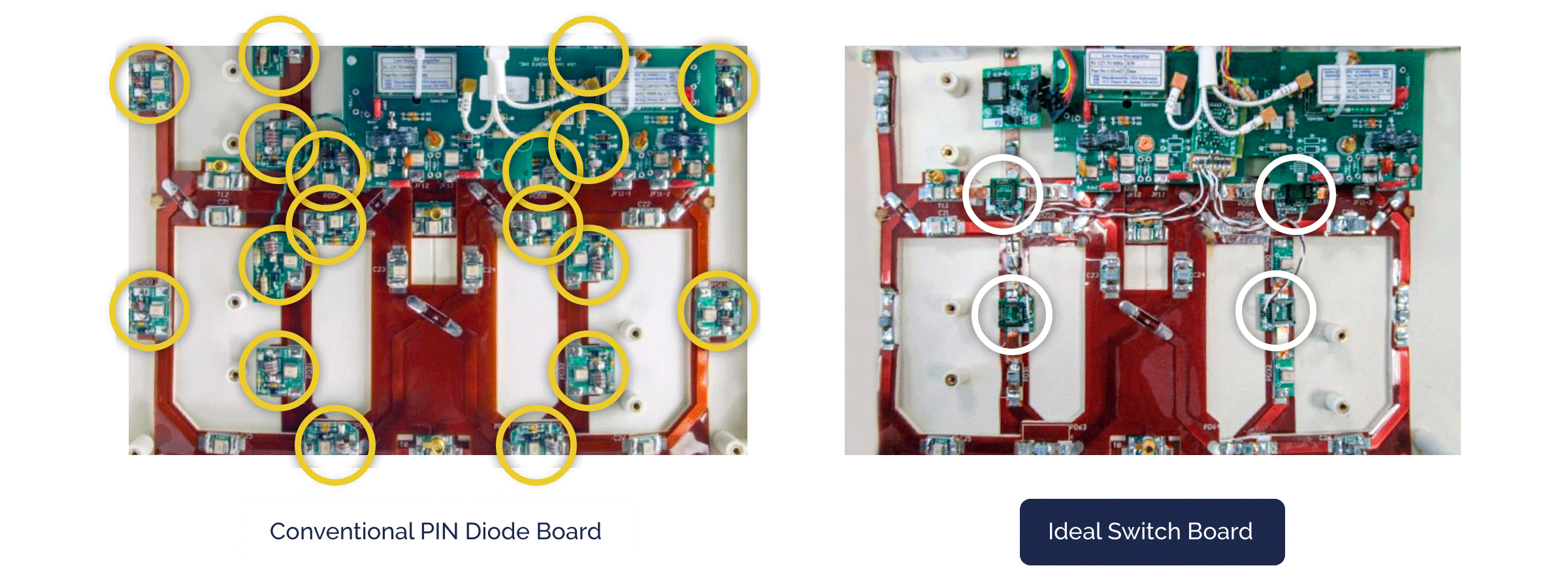

MRI machines use a lot of semiconductors like PIN diodes to manage high-voltage switching.

Hundreds of inefficient PIN diodes consume massive amounts of current, requiring complex thermal management solutions.

Thermal management and design complexity limit the ability to create smaller, more portable diagnostics.