BEAM

• Proprietary alloys

• High temperature capable

• Decades of life

CONTACT

• Low resistance

• Billions of operations

• No stiction

GATE

• Electrostatic = low power

• No charging

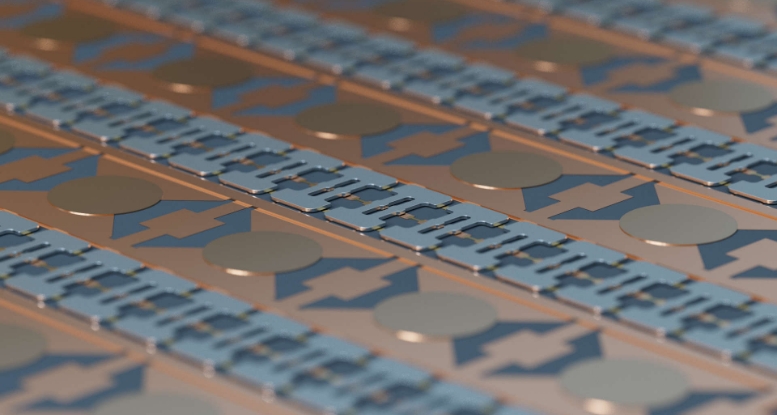

FROM UNIT CELL TO CELL ARRAY

Simple cell design makes it very small – 50μm x 50μm – and easy to pack in dozens or hundreds of switches on a die.

SCALABLE PRODUCTS

Configurable in series and/or parallel designs to create an infinite number of product configurations.

UNPRECEDENTED CURRENT DENSITY

Over 400 independent unit cells to create a miniaturized 10A array package.

SMART POWER RELAY

The world's first miniaturized smart power relay is enabled by the Ideal Switch. Featuring low profile, low power consumption, monitoring, and smart control.

NEXT-GENERATION POWER APPLICATIONS

Reductions in size and total cost of ownership, enable economical deployment of next generation distributed power applications.

BEAM

• Proprietary alloys

• High temperature capable

• Decades of life

CONTACT

• Low resistance

• Billions of operations

• No stiction

GATE

• Electrostatic = low power

• No charging

FROM UNIT CELL TO CELL ARRAY

Simple cell design makes it very small – 50μm x 50μm – and easy to pack in dozens or hundreds of switches on a die.

SCALABLE PRODUCTS

Configurable in series and/or parallel designs to create an infinite number of product configurations.

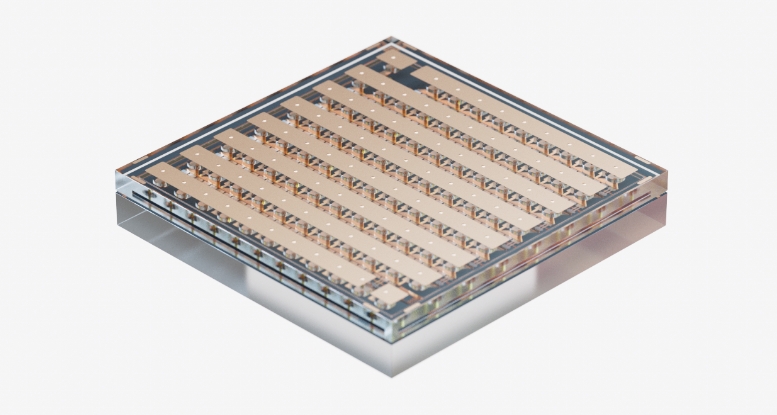

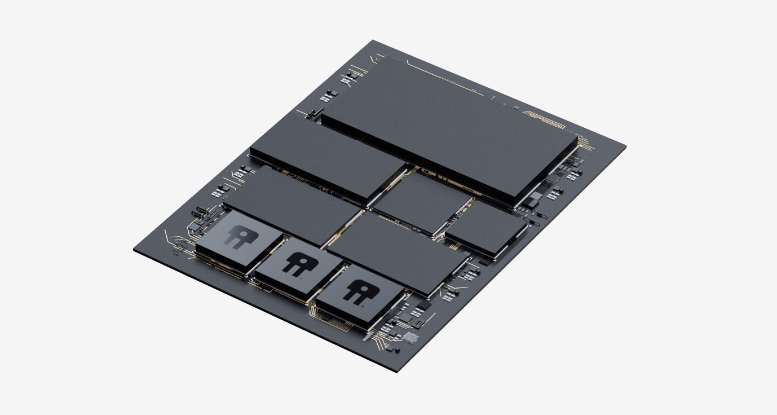

UNPRECEDENTED CURRENT DENSITY

Over 400 independent unit cells to create a miniaturized 10A array package.

SMART POWER RELAY

The world's first miniaturized smart power relay is enabled by the Ideal Switch. Featuring low profile, low power consumption, monitoring, and smart control.

NEXT-GENERATION POWER APPLICATIONS

Reductions in size and total cost of ownership, enable economical deployment of next generation distributed power applications.

BEAM

• Proprietary alloys

• High temperature capable

• Decades of life

CONTACT

• Low resistance

• Billions of operations

• No stiction

GATE

• Electrostatic = low power

• No charging

FROM UNIT CELL TO CELL ARRAY

Simple cell design makes it very small – 50μm x 50μm – and easy to pack in dozens or hundreds of switches on a die.

SCALABLE PRODUCTS

Configurable in series and/or parallel designs to create an infinite number of product configurations.

UNPRECEDENTED CURRENT DENSITY

Over 400 independent unit cells to create a miniaturized 10A array package.

SMART POWER RELAY

The world's first miniaturized smart power relay is enabled by the Ideal Switch. Featuring low profile, low power consumption, monitoring, and smart control.

NEXT-GENERATION POWER APPLICATIONS

Reductions in size and total cost of ownership, enable economical deployment of next generation distributed power applications.